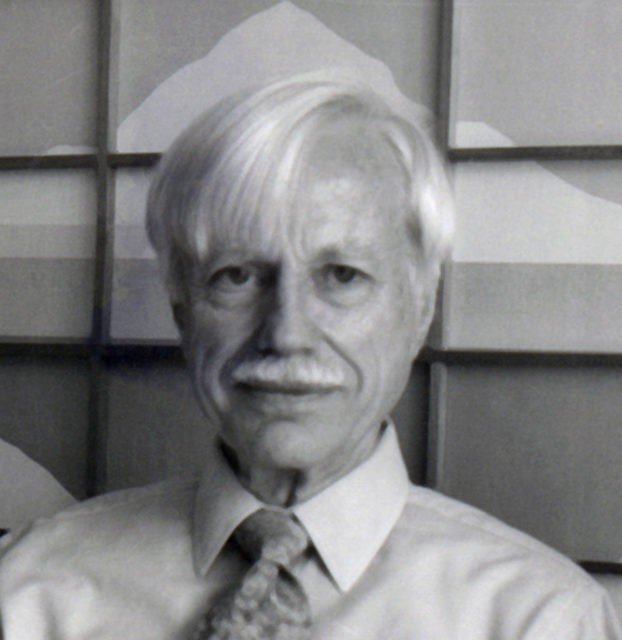

Don Shepherd

Artist Don Shepherd (1930–2002) studied at the California School of Fine Arts in San Francisco and later at the Catan-Rose Institute of Fine Art in Jamaica, New York, where he received a certificate of fine art in 1957. He was trained as an architect before working as a design designer for Blenko Glass Company from 1974 to 1988. Shepherd later joined former Blenko designer John Nickerson to hold demonstrations of their glass craft at the art departments of various institutions. Shepherd left Blenko in 1988 to design office furniture for Herman Miller.

Works

Green Transcending Head, 1981. Made with the assistance of Everett “Shorty” Finley at Blenko Glass Company. Green tinted transparent glass; blown, with copper metal inclusions; sandblasted; cemented to base. H: 39 cm, W: 18.3 cm. Collection of The Corning Museum of Glass, Corning, New York (81.4.121).

Candlestick (No. 802S Diamonds candleblock). Designed by Shepherd for Blenko Glass Company, made c. 1980-1981. Clear glass. H: 2.5 in, Diam: 2.5 in. Collection of the Museum of American Glass in West Virginia (2009.114.141).

Vase (No. 8433 top hat), Designed by Shepherd for Blenko Glass Company, made c. 1985. Clear glass with dimpled sides. H: 2.5 in, Diam: 5.625 in. Collection of the Museum of American Glass in West Virginia (2012.102.1).

Don Shepherd discusses Howard Ben Tré setting up an annealing oven at Blenko in a 1981 interview.

01:02 TranscriptDon Shepherd talks about being a designer for Blenko and making a mold made out of coat hangers in a 1981 interview with Paul Hollister.

1:51 TranscriptDon Shepherd talks about being a designer for Blenko and making a mold made out of coat hangers in a 1981 interview with Paul Holister.

01:51 Transcript